Peenya, Bangalore, Karnataka

- GST NO. : 29GJEPB3922B1ZM

48,000.00 / piece( + 18% GST applicable)

Get Best Price

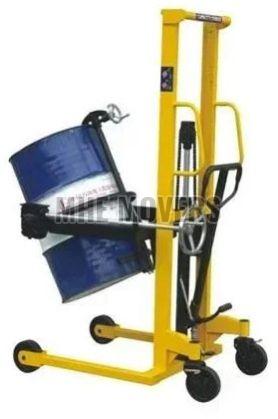

Service for Hydraulic Drum Stackers:

-

Routine Inspections:

- Hydraulic System Check: Inspect hydraulic fluid levels and ensure the system is free from contaminants. Low fluid levels or dirty fluid can lead to poor lifting performance and damage to the hydraulic pump or cylinder.

- Hydraulic Leaks: Inspect hoses, seals, and fittings for any signs of hydraulic fluid leaks. Even small leaks can affect the stacker’s ability to lift heavy loads and may also create safety hazards.

- Forks and Lifting Mechanism: Check the forks, lifting arms, and the lifting mast for any misalignment, wear, or damage. Ensure that the lifting mechanism is working smoothly and that the forks are not bent or cracked.

- Safety Features: Verify that safety features such as the overload protection system, safety locks, and emergency stops are functioning correctly. These are crucial for preventing accidents during operation.

-

Lubrication & Maintenance:

- Lubricate Moving Parts: Regularly lubricate the mast, chains, bearings, pivot points, and other moving parts to reduce friction, wear, and tear. This ensures smooth lifting and extending of the forks.

- Hydraulic Fluid Change: Over time, hydraulic fluid can degrade and become contaminated with debris. Regularly changing the hydraulic fluid is necessary to keep the system operating efficiently and prevent pump or valve failure.

- Tire & Wheel Maintenance: Inspect the tires and wheels for wear or damage. Hydraulic drum stackers often use heavy-duty wheels, which should be kept in good condition to maintain stability and mobility.

Request

Callback

Callback

Yes! I am Interested

Looking for "Hydraulic Drum Stacker Services" ?

pecice

Explore More Services