Peenya, Bangalore, Karnataka

- GST NO. : 29GJEPB3922B1ZM

Pallet Stackers

Leading Manufacturers, Wholesaler, Trader of Battery Operated Semi Electric Stacker, Battery Operated Stacker, Double Frame Hand Stacker, Electric Pedestrian Stacker, Fully Automatic Stacker, Fully Electric Stacker, Hydraulic Manual Stacker, Manual Hand Stacker, Self Propelled Stacker, Semi Electric Stacker and Straddle Manual Pallet Stacker from Bangalore.

| Business Type | Manufacturer, Supplier, Trader |

| Driven Type | Electric, Battery |

| Color | Yellow |

| Application | Lifting Goods |

| Certification | CE Certified |

| Warranty | 1year |

| Country of Origin | India |

MHE MOVERS

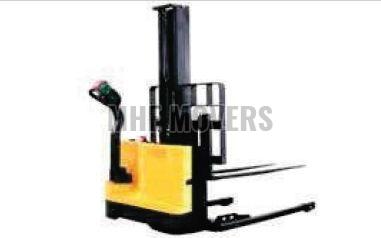

Battery Operated Semi Electric Stacker

Efficient and compact, this stacker combines electric lifting with manual steering.

Features a powerful battery for extended operation and enhanced lifting capability.

Ideal for stacking and transporting heavy loads in tight spaces.

Durable construction and easy-to-use controls for smooth operation.

Perfect for warehouses, retail, and material handling applications.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Driven Type | Battery |

| Lifting Capacity | 2 Ton |

| Lifting Height | 2 Meter |

| Structure | Master Channel 16mm Structure |

| Weight | 300 Kg |

| Size | 1500 x 800mm |

| Handle Length | 1000 mm |

| Gap Between Fork | 340 mm |

| Lifting Speed Mm Per Stroke | 20 mm |

| Operating Pressure Bar | 80 bar |

| Turning Radius | 1400mm |

Semi-electric stackers are a type of material handling equipment that combines manual operation with electric-powered lifting. They are commonly used in environments where moderate lifting and moving tasks are required but where full-powered equipment may be too costly or unnecessary. Here are some typical uses for semi-electric stackers:

**1. ** Warehousing and Storage

- Stacking Pallets: Ideal for lifting and stacking pallets of goods, making it easier to organize inventory in storage racks or shelves.

- Rearranging Stock: Facilitates the rearrangement of stock within warehouses, improving space utilization and access to inventory.

**2. ** Retail Environments

- Shelf Stocking: Assists in stocking high shelves or displays by providing electric-powered lifting to reach elevated areas safely.

- Display Arrangement: Useful for arranging and repositioning merchandise, especially in retail environments with high or bulky items.

**3. ** Manufacturing Facilities

- Material Handling: Moves raw materials, components, and finished products to and from production areas or assembly lines.

- Workstation Support: Provides access to elevated workstations or assembly areas, enhancing productivity and ergonomics.

| Business Type | Manufacturer, Supplier, Trader |

| Brand Name | MHE Movers |

| Country of Origin | India |

| Application | Industrial |

| Fork Length | 1000 Mm |

| Lifting Capacity | 1000 Kg |

| Material | Mild Steel |

| Lowered Fork Height | 85 mm |

MHE MOVERS

A Double Frame Hand Stacker is a manual material handling device designed for lifting and stacking loads. It features a sturdy double-frame structure for added stability and support, making it capable of handling heavier loads than standard hand stackers. The operator manually pumps the lift to elevate the load, and the stacker is ideal for use in narrow aisles or confined spaces in warehouses and factories.

| Business Type | Manufacturer, Supplier, Trader |

| Brand Name | MHE Movers |

| Driven Type | Electric |

| Type | Electric Stacker |

| Country of Origin | India |

| Height | 6300 mm |

| Lift motor rating S3, 15% | 3 kW |

| Travel speed | 5.5 km/h |

MHE MOVERS

Electric Pedestrian Stacker: An electric pedestrian stacker is a battery-powered material handling equipment designed for lifting and stacking goods in warehouses and storage areas. Operated by a pedestrian, it allows for efficient movement of pallets and other items over short distances, offering improved lifting capacity and control compared to manual stackers. It is ideal for tasks such as stock replenishment, inventory management, and loading/unloading in confined spaces.

| Business Type | Manufacturer, Supplier, Trader |

| Brand Name | MHE Movers |

| Driven Type | Electric |

| Automatic Grade | Fully Automatic |

| Application | Industrial |

| Type | Electric Stacker |

| Country of Origin | India |

| Material | Mild Steel |

MHE MOVERS

A Fully Automatic Stacker is an advanced material handling device designed for automated storage and retrieval of goods. It uses robotic technology to automatically lift, stack, and organize items in warehouses or distribution centers. These stackers enhance efficiency, reduce labor costs, and improve safety by eliminating manual intervention in material handling tasks.

| Business Type | Manufacturer, Supplier, Trader |

| Material | Mild Steel |

| Lifting Capacity | 2.5 Ton |

| Driven Type | Electric |

| Application | Lifting Goods |

| Warranty | 1year |

| Country of Origin | India |

| Fork Length | 900 Mm |

| Power Supply | AC |

| Fork Width | 740 mm |

MHE MOVERS

Fully Electric Stacker

Designed for efficient and effortless material handling, this stacker offers electric lifting and driving.

Equipped with advanced battery power for longer operation and increased load capacity.

Ideal for stacking, lifting, and transporting goods in tight spaces and high racking systems.

User-friendly controls ensure smooth and precise maneuvering.

Perfect for warehouses, manufacturing plants, and distribution centers.

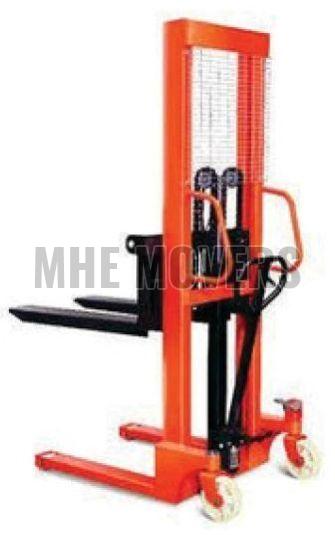

| Business Type | Manufacturer, Supplier, Trader |

| Driven Type | Hydraulic |

| Color | Black, Orange |

| Application | Lifting Goods |

| Type | Portable |

| Warranty | 1year |

| Country of Origin | India |

| Brand Name | MHE MOVERS |

| Max. Lifting Height | 5 Meter |

| Load Capacity | 500-1000kg |

MHE MOVERS

Hydraulic Manual Stacker

A durable and efficient solution for lifting and transporting heavy loads manually.

Features a robust hydraulic system for smooth and controlled lifting.

Compact design ideal for use in narrow aisles and tight spaces.

Perfect for warehouses, workshops, and light industrial applications.

Easy to operate with a manual pump and ergonomic handle for comfort.

| Business Type | Manufacturer, Supplier, Trader |

| Condition | New |

| Shape | Rectangular |

| Application | Industrial |

| Country of Origin | India |

| Lifting Capacity | 200-250 Kg |

| Material | Mild Steel |

| Fork Width | 10 mm |

| Delivery Time | 8DAYS |

MHE MOVERS

A Manual Hand Stacker is a compact and simple material handling tool designed for lifting and stacking loads manually. It typically features a hydraulic or mechanical lift system operated by a hand pump, allowing users to lift and position goods at various heights. Ideal for use in tight spaces or smaller warehouses, it provides an efficient solution for handling lighter loads without the need for electric power.

| Business Type | Manufacturer, Supplier, Trader |

| Driven Type | Electric |

| Color | Black, Orange |

| Condition | New |

| Application | Industrial |

| Type | Electric Stacker |

| Country of Origin | India |

MHE MOVERS

A Self Propelled Stacker is a type of material handling equipment that allows for both lifting and moving loads independently. It is equipped with an electric motor for driving, eliminating the need for manual pushing. This stacker can easily transport heavy loads and stack them at various heights, making it ideal for use in warehouses, distribution centers, and industrial environments where efficiency and mobility are essential.

| Business Type | Manufacturer, Supplier, Trader |

| Brand Name | MHE Movers |

| Driven Type | Electric |

| Color | Black, Orange |

| Automatic Grade | Semi Automatic |

| Application | Industrial |

| Type | Semi Electric Stacker |

| Country of Origin | India |

MHE MOVERS

A Semi Electric Stacker is a type of material handling equipment that combines manual and electric operation. It features an electric motor for lifting and lowering loads, while the movement (driving) is typically manual. Ideal for handling heavy loads in narrow aisles or tight spaces, semi-electric stackers are widely used in warehouses and factories for efficient stacking and transportation of goods.

| Business Type | Manufacturer, Supplier, Trader |

| Country of Origin | India |

| Warranty | 1year |

| Capacity | 500 Kg |

| Application | Material Handling |

| Color | Yellow |

| Driven Type | Hydraulic |

| Material | Mild Steel |

| Height | 10 Feet |

A manual straddle stacker is a type of equipment used for lifting and transporting pallets and other materials. It is designed with legs that straddle the load, allowing it to handle a variety of pallet sizes and types. Here are some common uses and advantages of manual straddle stackers:

**1. Warehouse Operations

- Pallet Stacking: Ideal for stacking and unstacking pallets in warehouse racks or shelves. The straddle design allows it to work with different types of pallet racking systems.

- Stock Movement: Assists in moving stock from storage locations to shipping areas or picking stations, improving warehouse efficiency.

**2. Loading and Unloading

- Truck Loading: Facilitates the loading and unloading of pallets from delivery trucks, reducing manual effort and improving productivity.

- Container Handling: Helps in moving pallets in and out of shipping containers or storage containers.

**3. Retail and Distribution Centers

- Stock Replenishment: Used to transport and restock goods from storage areas to sales floors or distribution areas, ensuring timely inventory replenishment.

- Product Handling: Assists in organizing and repositioning products within retail or distribution environments.